Exhaust Manifold Damage Validation

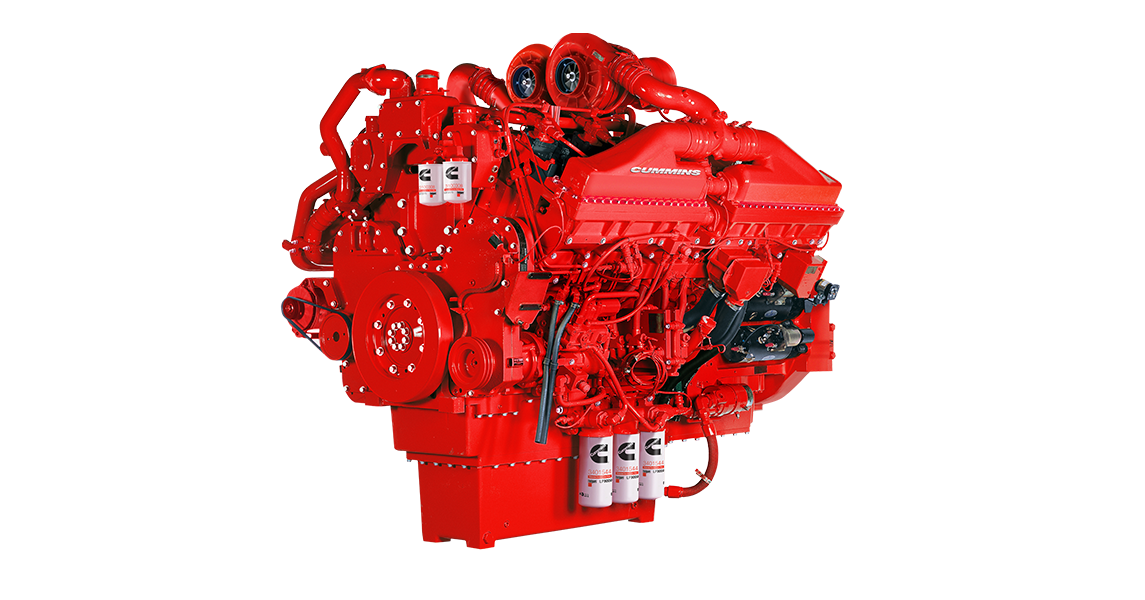

QSK38 - Marine Engine

I performed a damage factor analysis using a MATLAB-based damage simulation software tool for an exhaust manifold as a post-design investigative project. The exhaust manifold in question was tested without and with a heatshield on the unit in an abusive dyno test one year apart respectively. The manifold failed in the second dyno test with the heatshield on the unit. Preliminary damage model results show that the relative damage acquired by the heatshield unit dyno test is 4 times worse than the unit without a heatshield when using 6 hours of representative data for both cases. Due to a redesign in the manifold between the tests, recalibration of the damage model was done to a thermocouple location that was largely untouched in the redesign process. Calibrating the damage model to this location resulted in improved and representative damage results. This analysis provided general guidelines for heatshield applications and its thermal damage consequences for the Cummins' Power Supply Business Unit.

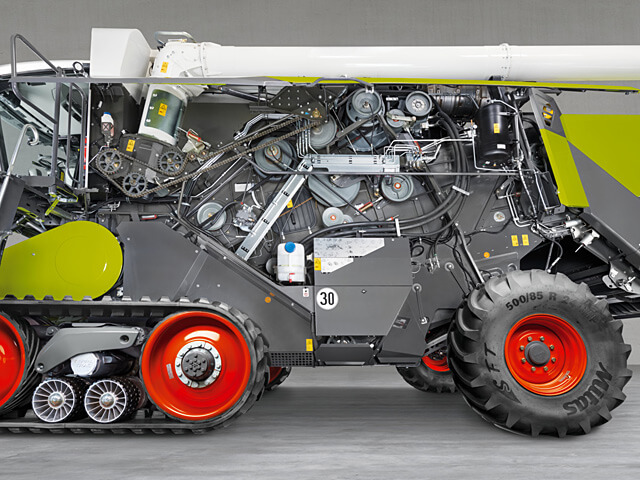

Barley L9 CLAAS

I performed a damage factor analysis using a MATLAB-based damage simulation software tool for the redesigned exhaust manifold specific to CLAAS Combine Harvester application for a P-Phase Design Review to determine a dyno test runtime. The application involved the uncertainty of the test unit having an OEM heatshield during the dyno test. The damage model was modified with heatshield virtual sensors to simulate the lack/presence of a heatshield in a representative dyno test cycle for the design team to make an informed decision on the test run time. I provided theoretical background and an in-depth damage factor analysis along with annotated raw input data for heatshield vs. no heatshield application.

Engineering Standards and Methodology

Exhaust Manifold Damage Modeling EP (Engineering Practice)

I authored an EP document that highlights how to run a successful damage factor model for Exhaust Manifolds geared towards EBU utilization with additional details on damage modeling theories, common errors and solutions, and best practices on data quality, management, and interpretation. This EP was proactively written to aid a future engineering standards task involving damage models and serves as a detailed user guide for engineers tasked with running a damage model for exhaust manifolds. This was created in collaboration with EBU users to document user feedback and experiences, the exhaust manifold standards owner, and the owners of DamageWise to verify information included in the EP.

Intake & Exhaust Throttle CES (Cummins Engineering Standards)

I am authoring a new CES document for performance and supplier testing standards for Intake Air Throttles and Exhaust Throttle Valves in collaboration with the standards owner. Using the EGR Valves CES as the backbone of the new CES, I edited the document for new component pronouns and related functional action items. I added new supplier tests to reflect warranty issues and referenced a new SAE Corrosion test in response to historical failures in the component. The testing flowchart was reformatted into a simpler and more readable design with the new tests and updated testing component part numbers.

Power Cylinder Damage Modeling

I worked with the Power Cylinder standards owner at Cummins to continue the review of power cylinder damage models and analysis of subsequent results to investigate the abusiveness of currently advised dyno test cycles. Preliminary work mainly dealt with High Cycle Fatigue, Low Cycle Fatigue, and Oxidation damage models for steel and aluminum pistons. Abnormal Relative Accumulated Damage (RAD) values were observed for both HCF and Oxidation models and were analyzed and resolved with correlations to math-based physics Simulink models and raw input data.