Fizeau Interferometer

Leibniz Universität Hannover

Introduction

High precision optics with low dimensional tolerances help to achieve technological advancements in numerous fields. Earlier methods of measurement for optical components were largely contact-based and prone to surface contamination i.e. tactile measurement with styli led to surface micro-scratches. The measurement of transparent optical surfaces is a challenge for optical measuring systems as they can only detect small optical signals. This results in the demand for a highly sensitive non-contact optical measuring system for optical components.

Challenge

The research task required the need for instant modification in setup, modularity in component utility, and flexibility in test parts. Additionally, there was an emphasis for the designed system to be a low-cost alternative to pre-built interferometers on the market for research use in labs and start-ups.

Solution

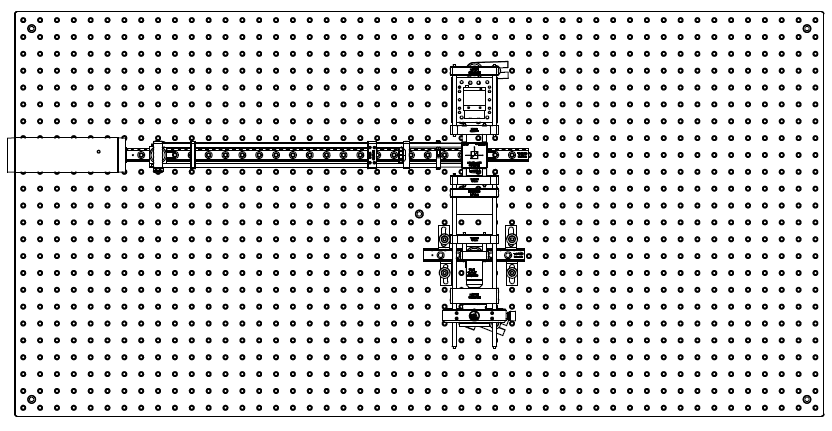

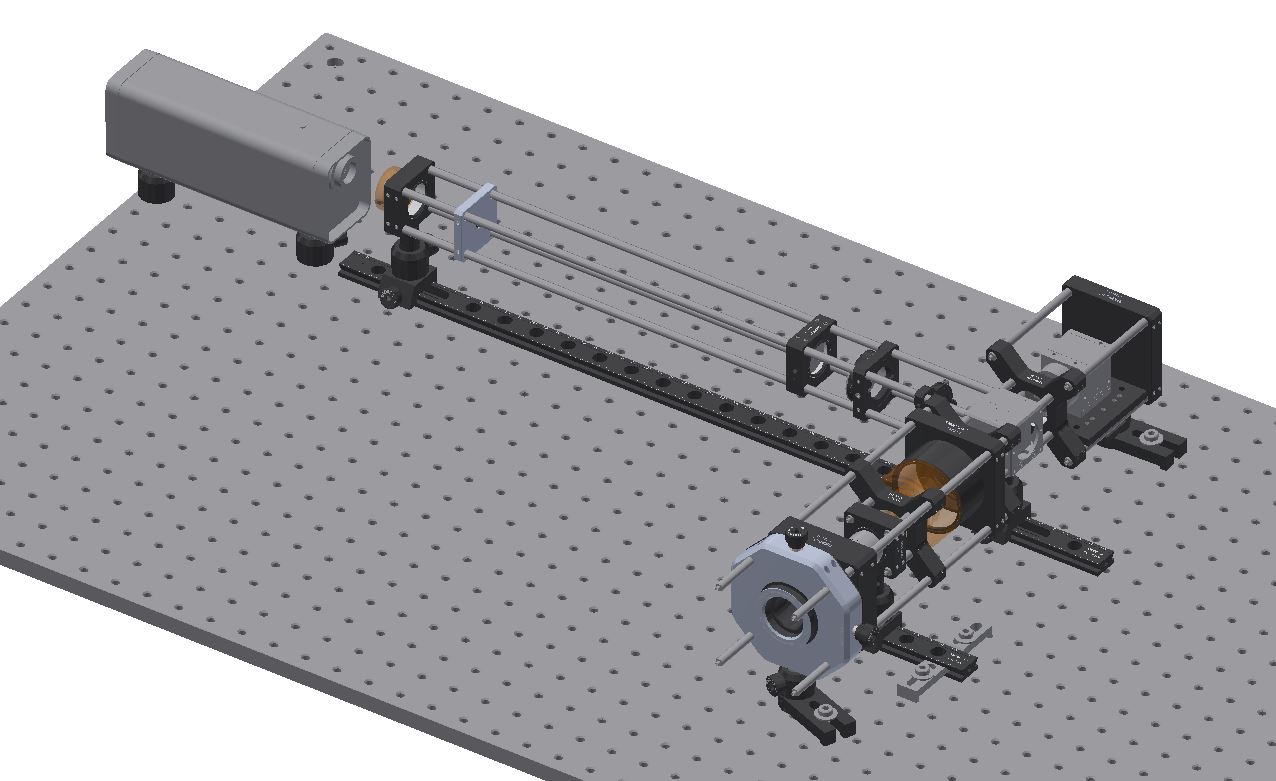

The process of deciding on a suitable type of interferometer to be built for nanometer-scale applications involved in-depth literature review on the build, applications, and utility of varying interferometers. I envisioned and proposed a deconstructed interferometer to be assembled ona large non-reflective magnetic breadboard to achieve modularity and extreme customization of experimental setup.

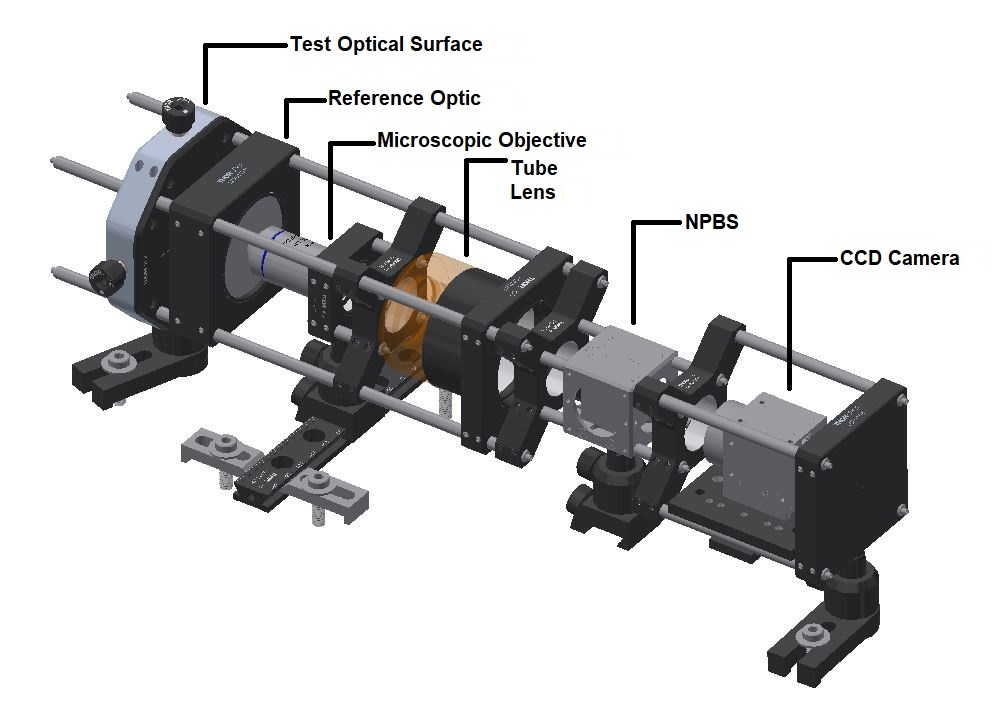

Using an existing schematic of a Fizeau Interferometer, journal articles on interferometry, and Autodesk Inventor, I assembled compatible optical components to precisely magnify, collimate, phase-shift, and reflect a Helium-Neon laser onto a CCD camera to be digitally analyzed on a computer.

Design Testing

- Dovetail optical rail system to facilitate one-dimensional movement of optomechanics for customization

- Aluminum optical cage system to ensure radial alignment of circular optical components

- Deconstructed & custom collimated beam expander to reduce error caused by inhomogeneity in Gaussian Beams 60mm to 30mm cage plate adapter with a drop-in 30mm cage plate to mount 1 inch test optics

- XYZ translation mount to enable custom experimental setups along test tracks